AI-Based Vehicle Damage Repair Price Estimation System

Copyright ⓒ 2023 The Digital Contents Society

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-CommercialLicense(http://creativecommons.org/licenses/by-nc/3.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Artificial intelligence-based estimation of repair costs for damaged vehicles is an emerging field that relies on artificial intelligence and computer vision systems to automatically generate accurate cost estimates. This area of research is becoming increasingly important owing to its potential to streamline the automotive repair industry, enhance overall transparency, improve the accuracy of cost estimation, and expedite insurance claims processing. This paper proposes the identification of the make and model of a vehicle, classification of the damaged vehicle type, and estimation of repair costs based on prices from various vehicle manufacturers. The proposed method for achieving state-of-the-art performance and time-saving in this system is through the use of ResNet50 and transfer learning. We propose a vehicle make and model classification module as well as a damaged vehicle classification module based on ResNet50 and transfer learning to improve the accuracy of the results. The accuracy of vehicle make and model classification module is 88%, which is approximately 11% higher than that of other studies. The accuracy of damaged vehicle classification module in this study is 86%, which is 67% higher than that of other studies.

초록

인공지능 기반의 손상 차량 수리비용 견적은 인공지능 및 컴퓨터 비전 시스템에 의해서 정확한 비용 견적을 자동으로 생성하는 새로운 분야이다. 이 연구 분야는 자동차 수리 산업을 효율화하고, 전반적인 투명성과 비용 추정의 정확성을 높이고, 보험금 청구 처리를 신속하게 처리할 수 있는 잠재력 때문에 점점 더 중요해지고 있다. 본 논문에서는 다양한 차량 제조사의 가격을 기반으로 차량의 제조사와 모델의 식별, 손상 차종의 분류, 수리비 견적 등을 제안한다. 이 시스템에서 최첨단 성능과 시간 절약을 달성하기 위해 제안된 방법은 ResNet50과 전이 학습을 통해 수행된다. 본 논문에서는 ResNet50 기반의 차량 메이커 및 모델 분류 모듈과 손상 차량 분류 모듈 및 결과의 정확도 향상을 위한 전송 학습을 제안한다. 제안한 시스템에서 차량 메이커 및 모델 분류 모듈의 정확도는 88%로 기존 연구에 비해서 약 11% 높은 수준이며, 본 논문에서의 손상 차량 분류 모듈의 정확도는 86%로 기존 연구에 비해서 약 67% 높은 수준이다.

Keywords:

Vehicle Damage, Object Detection, Vehicle Make and Model Classification, ResNet50, Image Classification키워드:

차량 손상, 객체 탐지, 차량 제작 및 모델 분류, 이미지 분류Ⅰ. Introduction

According to the report “Risk Challenge: Property and Casualty Insurance Opportunity Evolution to 2040” released by Ruizai Research Institute in September 2021, global auto insurance premiums will reach $766 billion in 2020, accounting for about 42% of the property and casualty insurance business. The global auto insurance market is estimated to be $789.4 billion in 2021. As the number of cars increases, so does the number of auto accidents, but insurance companies' estimates of accident identification and repair costs still rely on worker's inspection reports of each damaged vehicle[1].

Due to the limitations of worker detection, such as long time and low accuracy, the insurance company wastes a lot of funds, and the claim process is complicated, wasting the time of users. In recent years, with the development of computer vision and artificial intelligence technology, this technology has been applied to insurance companies[1].

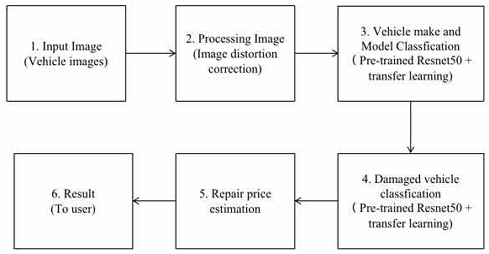

This paper proposed a system to estimate the cost of vehicle repair by using ResNet50 and Transfer learning. This algorithm mainly consists of three modules: Vehicle make and model classification module, damaged vehicle classification module, and repair price estimation module. First, identify the make and model of the vehicle, classify the damaged vehicle type, estimate the cost of repairing the vehicle based on the price from the different vehicle manufacturer, then decide whether to repair or replace it according to the repair price of the vehicle.

Through this automated vehicle damage classification and repair price estimation based on AI(Artificial Intelligence), we can achieve more efficient, accurate and objective vehicle damage assessment, which will improve the efficiency of the insurance and vehicle markets, reduce disputes and provide a better user experience.

This paper served as preliminary for evolutions in vehicle damage repair price estimation technology with the aid of rapidly advance AI. According to some related studies, the use of AI technology can solve the problem of slow efficiency in using traditional employees to classify vehicle damage type and price estimates. Through research on radial distortion, ResNet50(Residual Network 50), transfer learning, and Go Programming technology, this paper proposes to use the ResNet50 and transfer learning algorithm. Based on this algorithm, three modules are designed to estimate the price of the repair damaged vehicle. Through the results and performance analysis of each module, the accuracy has a greatly improved. The results of this paper show that the use of AI technology can advance the development of technology for vehicle damage repair price estimation.

Ⅱ. Related Works

2-1 Radial Distortion for image processing

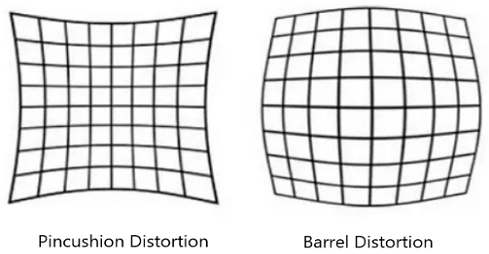

Image distortion correction is a process used to correct image distortion caused by lens aberrations or camera characteristics. There are two main types of lens aberration: radial and tangential. Radial distortion[2] is the most common type of distortion and is caused by the shape of the lens and the refraction of light. Fisheye and wide-angle lenses are more prone to radial aberration. Radial aberration can be divided into two subtypes: Radial distortion can be divided into two subtypes: Barrel Distortion and Pincushion Distortion. Barrel distortion bends pixels near the center of the image outwards, while pincushion distortion bends pixels near the center of the image inwards.

2-2 ResNet50 for Object Classification

ResNet50[3] was proposed by Kaiming He and others at Microsoft Research in 2015. It is an important member of the ResNet family. ResNet50 has a deeper network structure than the traditional CNN (Convolutional Neural Network)[4] model. It solves the gradient disappearance problem during deep network training by introducing residual connections, effectively improving the performance of the model.

2-3 Transfer Learning for Improve System Performance

Transfer learning[5] is a branch of deep learning that aims to use similarities between data, models to transfer knowledge learned in one domain to a new domain. In layman's terms, transfer learning is the use of existing knowledge to learn new knowledge.

One of the most commonly used transfer learning methods is to use pre-trained models for fine-tuning, i.e. the user selects a model that has been successfully trained for a new task from PaddleHub based on the scene of the current task, and the dataset once used by the model is similar to the dataset of the new scene, and then only needs to fine-tune the parameters of the model using the data of the new scene during training of the current task scene(fine-tune), which can be used to learn a new task.

The model parameters can be fine-tuned using the data from the new scenario to complete the training model.

2-4 The Go Programming Language for System Application

Golang(Go Programming Language)[6] is a powerful programming language for building high-performance, highly concurrent API(Application Programming Interface) servers. It simplifies in many ways, enabling developers to quickly build reliable and efficient back-end applications.

Ⅲ. Proposed Vehicle Damage Repair Price Estimation System

3-1 Design Philosophies

The basic design ideas of this paper mainly include six steps. It mainly uses pre-trained ResNet50, transfer learning, vehicle make and model dataset and vehicle damaged dataset. Datasets are built by sites such as Stanford Cars dataset. Using ResNet50 and transfer learning to train model, the vehicle make and model was detected and classified, and the damaged vehicle was classified. According to the price of the different vehicle make and different damaged type, to estimate the price of the repaired damage vehicle.

3-2 Function Description

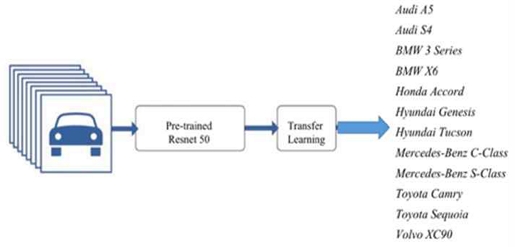

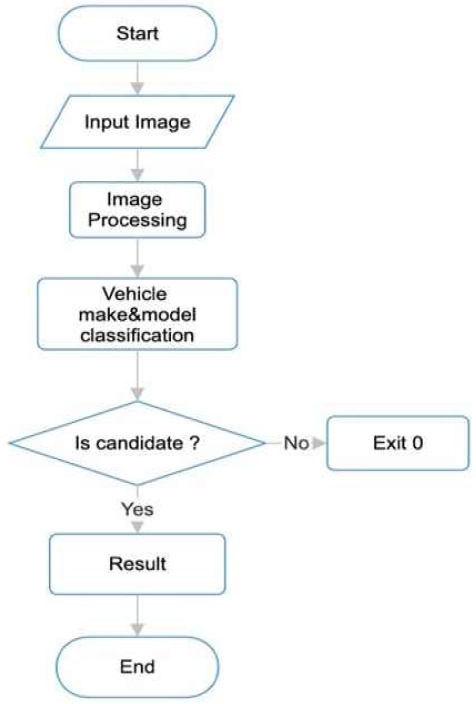

This module[7],[8] is designed to classify the make and model of the vehicle. This module mainly consists of dataset, ResNet50 and transfer learning, as shown in Fig. 3. During the inspection process, the make and model of the vehicle in the picture are classified, and the results are then used as parameters to estimate the cost of damaged vehicle repair.

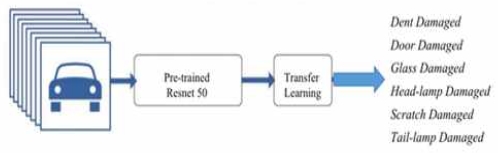

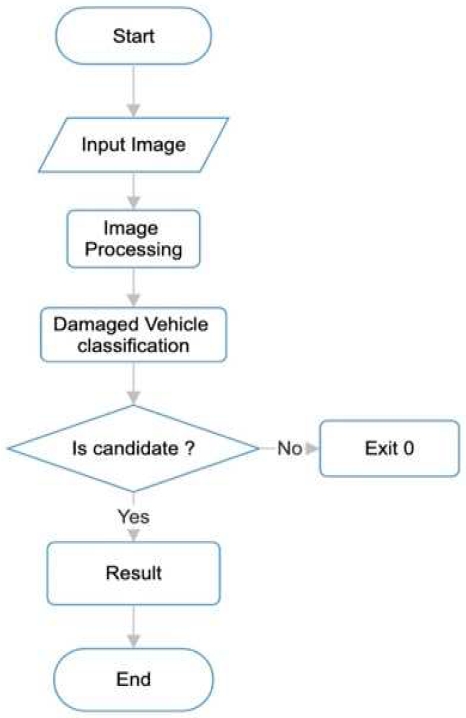

This module[9]-[11] is classify the vehicle damages such as dent damaged, door damaged, glass damaged, head-lamp damaged, scratch damaged, tail-lamp damaged as shown in Fig. 4. Then using the Green's theorem [12],[13] to calculate the area of the damaged part.

According to the area of the damaged part, and the price for each type of damage by different vehicle manufacturer is estimated to be the price range for repairing damaged vehicle.

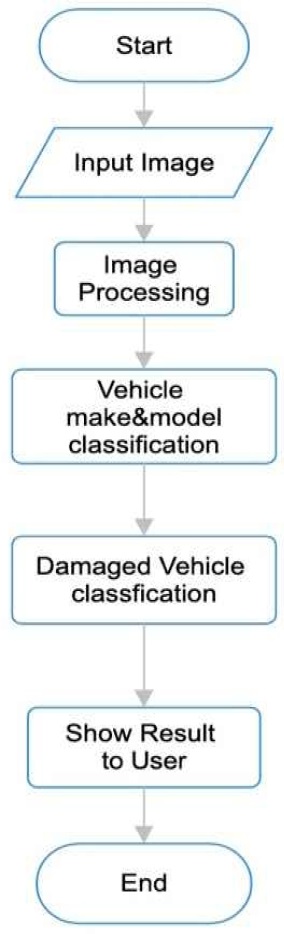

3-3 System Design

The system proposed in this paper consists of five steps. First, input image, process the input image, use ResNet50 and transfer learning to perform vehicle make and model classification, damaged vehicle classification[8], calculate the area according to the damaged vehicle, and calculate the range of cost for repair the vehicle based on the quotation from the vehicle manufacturer, and finally the results are show to the user. The flow chart of the proposed system is shown in Fig. 5.

In real life, image distortion correction can be performed to passively improve the accuracy of image recognition, as user's shooting methods and equipment vary widely. When radial aberrations in an image need to be corrected, camera parameters and OpenCV(Open Source Computer Vision) libraries are usually used to perform this operation.

Here are more detailed steps on how to correct radial distortion:

- a. Calculate the focal length and image center: First, the focal length and image center of the camera must be calculated. This is usually done using the width and height of the image. The focal length is usually set to half the width and height of the image, and the center is half the coordinates of the width and height of the image.

- b. Create the camera matrix: The camera matrix consists of the focal length and image center information and a fixed value of 1. This matrix is a necessary parameter for aberration correction.

- c. Set the radial distortion coefficients: Typically, the radial distortion coefficients(dist_coeffs) consist of four coefficients that describe the degree of curvature of the radial distortion. These coefficients are usually provided by the camera's calibration data. If you don't have calibration data, you can try to use the default values.

- d. Correct the radial distortion: Use the cv2(OpenCV library)[14] undistort function to correct radial distortion on the input_image. This will result in a corrected image(undistorted_image).

Using the pre-trained ResNet50 model as a base, model training can be accelerated by fine-tuning the last fully connected layer, since the model has already been trained on large amounts of data, this improves the performance of the model when using transfer learning. The flow chart of vehicle make and model classification is shown in Fig. 7.

- a. Model Construction: First, this paper loads a pre - trained ResNet50 model “model_ft”, which is a deep convolutional neural network for image classification tasks. Then, the last fully connected layer of the model is modified to adapt to a new classification task that requires classifying images into 196 different categories(vehicle make and model classification task).

- b. Data preprocessing and loading: The program defines the transformation operations for data preprocessing, including image resizing, data enhancement, and normalization. It then loads the training and test datasets using “torchvision. datasets.ImageFolder” and creates “trainloader” and “testloader data loaders” for batch loading of data. These data loaders will provide training and test data for the model to use.

- c. Model training: The program uses the “train_model” function to train “model_ft”. During the training process, the model continuously learns through multiple training model, using the loss function and the optimizer to adjust the weights. The program records the loss and accuracy of each training cycle for performance evaluation and analysis.

- d. Learning Rate Scheduler: The program creates a learning rate scheduler “lrscheduler” that dynamically adjusts the learning rate based on the performance of the model. This helps to optimize the training process of the model so that the learning rate can be adapted to different stages of training.

- e. Evaluation of model performance: At the end of each training model, the program prints the training time, loss, and accuracy for this model. This helps to monitor the performance of the model on the training data.

- f. Results Logging: The program stores the trained model “model_ft” as well as the loss and accuracy of each training model in the corresponding variables for analysis and visualization.

In summary, this section is a complete deep learning training flow for building, training, and evaluating a pre-trained ResNet50 model to perform the vehicle make and model classification module.

The synoptic vehicle damaged vehicle classification is similar with the vehicle make and model classification described in section 3.2 of this paper, but with some differences. The flow chart of damaged vehicle classification is shown in Fig. 8.

The process of damaged vehicle classification:

- a. Model construction: as in the vehicle make and model classification module, a pre-trained convolutional neural network model(e.g., ResNet 50) is first loaded. Then, the last layer of the model is modified to fit a new task, i.e., to classify damaged types in vehicle.

- b. Data preprocessing and loading: For the damaged vehicle classification task, an image dataset containing different type damaged vehicle must be prepared. The data preprocessing is similar with image resizing, data enhancement and normalization. The data loader is used to load the training and testing datasets.

- c. Model Training: Train the model to learn how to classify the damaged vehicle types. During training, weights are adjusted using appropriate loss functions and optimizers.

- d. Learning rate scheduler: To better control the training process, a learning rate scheduler can be used to automatically adjust the learning rate to speed up the convergence of the model.

- e. Model performance evaluation: At the end of each training model, evaluate the performance of the model on the training data, including recording the training time, loss, and accuracy. This helps to understand the performance and progress of the model.

- f. Log results: Store the trained model along with loss and performance data for each training model for analysis.

Since the price will change according to the market changes, it is necessary to enter the database according to the unit price of each damage type given by each vehicle manufacturer for each model. Then the unit price is multiplied by the area to get the final price, and the result is show to the user.

Ⅳ. Experiments and analysis

In this paper, the vehicle make and model classification module, and damaged vehicle classification module were implemented and tested.

4-1 Experiments

Datasets for three models were collected through website searches as shown in Table 1.

Three Datasets of three proposed modules are labeled as shown as Table 2.

4-2 Proposed Module Evaluation

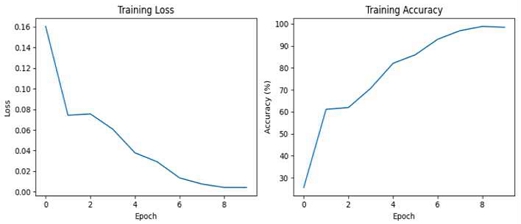

In this paper, we use training loss and training accuracy as performance metrics for training model. And confusion matrix is a valuable tool for evaluating the performance of a classification model by providing insights into the types of errors it is making. From the confusion matrix, various performance metrics can be calculated, including the precision, recall, f1-score, support, accuracy.

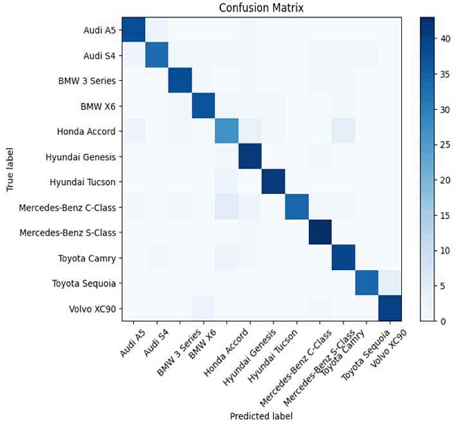

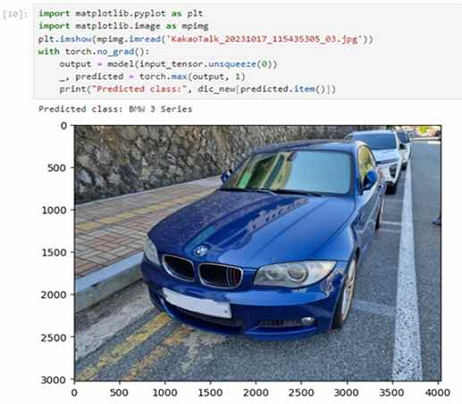

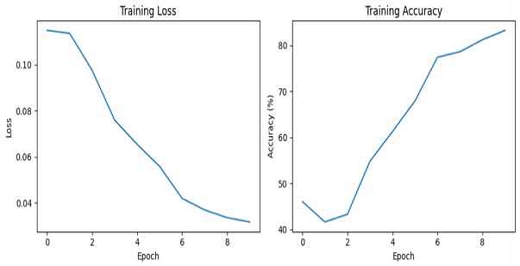

In this section, we describe the results for Vehicle make and model Classification module. Training Loss and Training Accuracy is shown in Fig. 9, Confusion Matrix is shown in Fig. 10, Performance of precision, recall, f1-score, support, accuracy is shown in Table 5, and the result image is shown in Fig. 11.

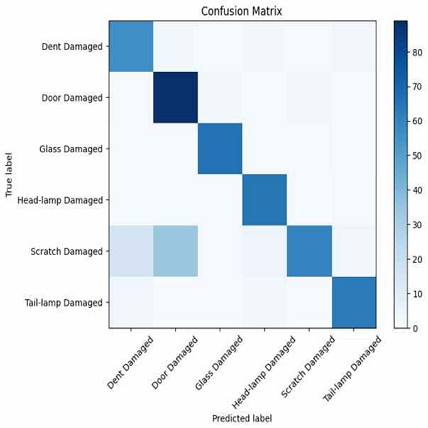

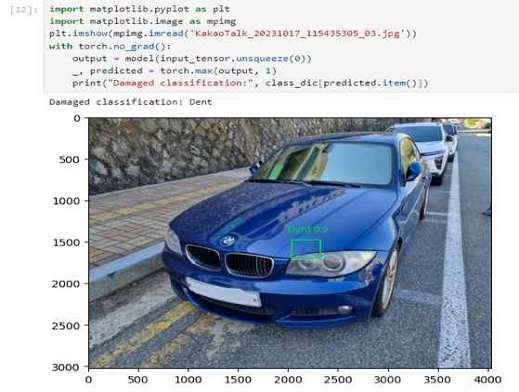

In this section, we describe the results for damaged vehicle Classification module. Training Loss and Training Accuracy is shown in Fig. 12, Confusion Matrix is shown in Fig. 13, Performance of precision, recall, f1-score, support, accuracy is shown in Table 6, and the result image is shown in Fig. 14.

4-3 Analysis

According to the testing environments in Table 3, and the tuning and training parameters of proposed modules in Table 4, the result is shown in Table 6. The accuracy of vehicle make and model classification module is 88%, the accuracy of damaged vehicle classification is 83%. Compare with the reference[11], the result shown Table 7.

The accuracy of vehicle make and model classification module is 77%, the accuracy of damaged vehicle classification is 19%. Using transfer learning based on ResNet50, the accuracy is improved. Therefore, ResNet50 and transfer learning method used in this system.

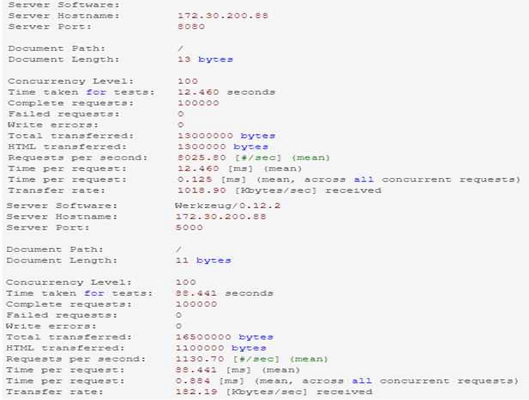

Flask total time 88.441 seconds, averaging 1130 requests per second. Go took 12.46 seconds to process 8025 requests per second. Compared to Go processing speed has increased in Fig. 15, in the test also found that in the use of Flask does not support large concurrency, if the concurrency in more than 200 will be easy to report an error, and Golang's concurrency up to 1,000 can be run normally, so Golang is more in line with the actual production environment required.

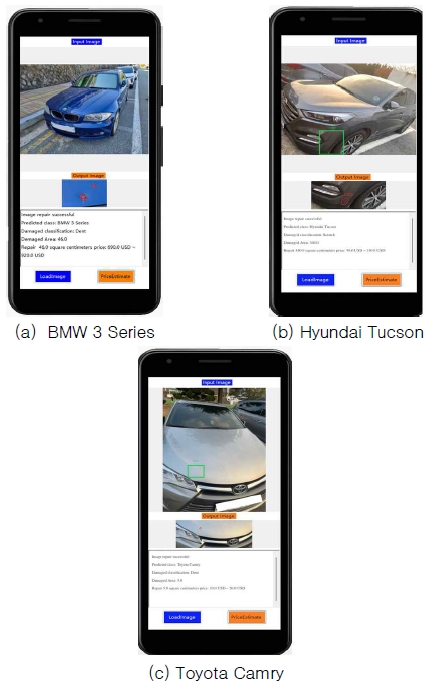

4-4 System Result

The system result image is shown in Fig. 16. Firstly, submit the input image, then will get the image of the broken parts. The last text box outputs the model of the vehicle, as well as the type of damage and the area of damage. Finally, according to the price of the different type of vehicle and different damaged types to calculate the repair price range of the vehicle.

Ⅴ. Conclusion and Future Works

From some related studies, I founded that the accuracy of classifying vehicle brand and model, damaged type and damage area is low, resulting in large price estimation errors. In order to solve this situation, I proposed to use ResNet50 as the basic network structure, and then use transfer learning to optimize parameters and improve accuracy.

In this paper, A system for repair price estimation based on damaged vehicle is presented. The accuracy of vehicle make and model classification module in this paper is higher 11% than that of reference[11], The accuracy of damaged vehicle classification module in this paper is higher 67% than that of Reference[11]. Therefore, the ResNet50 and transfer learning is used in this system. In future work, we will use more pre-trained CNN models with a large dataset to improve the accuracy, it can predict the price of repairing a damaged vehicle to be more reliable and accurate.

References

-

D. Rowell, S. Nghiem, and L. B. Connelly, “Empirical Tests for Ex Post Moral Hazard in a Market for Automobile Insurance,” Annals of Actuarial Science, Vol. 16, No. 2, pp. 243-260, July 2022.

[https://doi.org/10.1017/S1748499521000191]

-

M. Brown and D. G. Lowe, “Automatic Panoramic Image Stitching Using Invariant Features,” International Journal of Computer Vision, Vol. 74, No. 1, pp. 59-73, August 2017.

[https://doi.org/10.1007/s11263-006-0002-3]

-

D. Sarwinda, R. H. Paradisa, A. Bustamam, and P. Anggia, “Deep Learning in Image Classification using Residual Network (ResNet) Variants for Detection of Colorectal Cancer,” in Procedia Computer Science, Vol. 179, pp. 423-431, 2021.

[https://doi.org/10.1016/j.procs.2021.01.025]

-

B. Tugrul, E. Elfatimi, and R. Eryigit, “Convolutional Neural Networks in Detection of Plant Leaf Diseases: A Review,” Agriculture, Vol. 12, No. 8, 1192, August 2022.

[https://doi.org/10.3390/agriculture12081192]

-

Z. Zhu, K. Lin, A. K. Jain, and J. Zhou, “Transfer Learning in Deep Reinforcement Learning: A Survey,” IEEE Transactions on Pattern Analysis and Machine Intelligence, Vol. 45, No. 11, pp. 13344-13362, November 2023.

[https://doi.org/10.1109/TPAMI.2023.3292075]

-

Y. Kim, S. Oh, D. Lee, and S. Oh, “Performance Evaluation of Encoder-X in a Golang-Based Microservices Environment,” Journal of Contents Computing, Vol. 2, No. 2, pp. 199-206, December 2020.

[https://doi.org/10.9728/jcc.2020.12.2.2.199]

-

Y. Ren and S. Lan, “Vehicle Make and Model Recognition Based on Convolutional Neural Networks,” in Proceedings of the 7th IEEE International Conference on Software Engineering and Service Science (ICSESS), Beijing, China, pp. 692-695, August 2016.

[https://doi.org/10.1109/ICSESS.2016.7883162]

-

H. He, Z. Shao, and J. Tan, “Recognition of Car Makes and Models from a Single Traffic-Camera Image,” IEEE Transactions on Intelligent Transportation Systems, Vol. 16, No. 6, pp. 3182-3192, December 2015.

[https://doi.org/10.1109/TITS.2015.2437998]

- M. H. Thar, M. Zhang, G. H. Nam, and D. M. Lee, “Vehicle Damage Volume Level Recognition Algorithm based on Convolution Neural Network and Yolo Model,” in Proceedings of 2022 International Conference on Communication and Computer Research (ICCR 2022), Seoul, pp. 21-22, November 2022.

-

N. Dhieb, H. Ghazzai, H. Besbes, and Y. Massoud, “A Very Deep Transfer Learning Model for Vehicle Damage Detection and Localization,” in Proceedings of the 31st International Conference on Microelectronics (ICM), Cairo, Egypt, pp. 158-161, December 2019.

[https://doi.org/10.1109/ICM48031.2019.9021687]

-

M. K. Phyu and K. Woraratpanya, “Car Damage Detection and Classification,” in Proceedings of the 11th International Conference on Advances in Information Technology (IAIT2020), Bangkok, Thailand, 46, July 2020.

[https://doi.org/10.1145/3406601.3406651]

- K. F. Riley, M. P. Hobson, and S. J. Bence, Mathematical Methods for Physics and Engineering, 3rd ed. Cambridge, UK: Cambridge University Press, 2006.

- S. Lipschutz, D. Spellman, and M. R. Spiegel, Vector Analysis, 2nd ed. New York, NY: McGraw-Hill, 2009.

- I. Culjak, D. Abram, T. Pribanic, H. Dzapo, and M. Cifrek, “A Brief Introduction to OpenCV,” in Proceedings of the 35th International Convention MIPRO, Opatija, Croatia, pp. 1725-1730, May 2012.

저자소개

2017년 7월:Henan University (Bachelor)

2019년 5월:Pace University (Master)

2022년 3월~현 재: 동명대학교 컴퓨터미디어공학과 박사과정

*관심분야:AI, 딥러닝, 빅테이터, CNN

2001년 2월:충북대학교 수학과 (이학박사)

2004년 8월:충북대학교 컴퓨터공학과 (공학박사)

2005년 3월~현 재: 동명대학교 정보보호학과 교수

*관심분야:네트워크 보안, 딥러닝, IoT, 데이터분석